utilisation de broyeur mobile rm100 d équipement GitHub

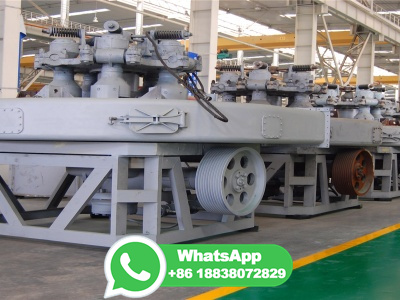

utilisation tamis concasseur Heavy Industry is a manufacturers of jaw Crusher,cone Crusher,sand making machine,vsi impact crusher,mobile crusher plant and vertical mill,ultra fine grinding,tricyclic medium speed micro grinding,coarse powder,pulverized coal mill,Raymond d'équipement de broyage du béton ...